News

Orbital Polisher, Rotary Buffer, and Dual Action Polishers

Orbital Polisher, Rotary Buffer, and Dual Action Polishers

Orbital Vs. Rotary Polishers

Many times it is asked what is the best polisher? The truth is that the best polisher or buffer will depend on the person and their intended use. While there is no one size fits all solution there certainly are better choices for some users than others.

There are many types of polishers one can choose from between types, brands, sizes, cordless, and so on. Today we are going to quickly review the two most common type of polishers or buffers and the difference between them. By the end of this article we hope you can easily select the buffer that is right for you.

Why Choose A Buffer?

First we answer the question, why choose a buffer?

Well in many cases when the upmost perfect finish is required by an enthusiast, detailer, collector, or hobbyist, using a buffer is the best way to achieve those results.

Often times one will try to polish a vehicle's surface by hand, only to find themselves tired and the appearance of a mildly improved surface.

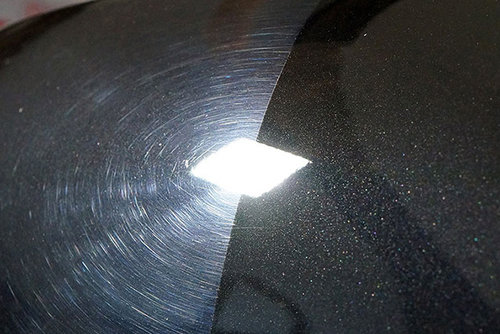

The most common use of a buffer of course is to remove scratches and swirl marks. Below we review a picture that best describes the surface of a vehicles finish.

In order to remove these scratches, you will need to remove enough paint surrounding the scratches in order to make the surface level. As you can see in this example, removing the scratches will require removing quite a bit of paint material, and in the case of the deeper scratch (where the arrow is pointing), you will not be able to completely remove it without exposing the base, or color coat of paint. This is a situation where you are better off reducing the edges of the scratch, filling in with touch up, wet sanding and polishing, but not completely removing the scratch.

Rotary Buffers

These machines are different in the way they work compared to orbital buffers.

The drive unit used in a rotary buffer is referred to as a direct drive, where the backing plate attaches is thus driven directly off the electric motor. This results in a single rotating motion. This rotating motion is typically clockwise as you look at the rotary buffer from behind.

Because the rotary buffer spins in one direction it can easily generate a massive amount of heat. The term "burning" the paint often refers to using a rotary polisher incorrectly and heating the paint to the point it is melted or removed from the base. This can happen when working one area to long. The heat being generated is a side effect of sorts of the great amount of force behind the buffer. This same power is what makes a rotary get a job done quickly and effectively. This type of machine is best used by someone with experience behind a buffer or someone who has a test vehicle to learn on before using it on something more valuable.

If your a professional or an enthusiast ready to add a more professional tool to your arsenal than something like a Flex PE-14-2-50 is the best choice for you. A German made unit, the machine will last for years to come in even the most harshest environments.

Random Orbital Polisher

Random orbital polishers are often a better choice for those in a professional environment but particularly an at home enthusiast. The speed of a random orbit polisher is counted in orbits per minute (OPM). Unlike a rotary which is forced to spin in one consistent direction, a random orbit polisher actually rotates from the momentum created by the high speed orbital motion. There is no rhyme or reason for which direction the unit will be driven making this machine very safe and easy to use for beginners. The pattern is random and is dependent upon the combination of stroke length, pad size, pad grip, and speed which can alter the pattern of motion. A great choice for an orbital would be the Griot's Garage Random 6' Orbital. An affordable well built unit for anyone.

Dual Action

Dual Action Polishers or DA's as they’re more commonly referred to, spin in 2 different ways: the head spins in a concentric circular action on a spindle which in turn spins in a wider circulating motion. The resulting oscillation creates a “wobble” which prevents excess heat and friction build up, but still allows enough such that light to moderate imperfections can be removed. This is a combination of sorts of a orbital and offers a bit different experience.

Forced Rotation Dual-Action Orbital Polishers

Lastly, there is a hybrid version something between the DA and a rotary. What this polisher does is combine both the rotary and orbitals motions into one forced action. What that means is this polisher not only orbits but it also rotates too, at the same time. A random orbit only drives orbit and relies on momentum to rotate the pad. These machines force both orbit and rotation. This means that a forced rotation dual action orbital polisher has a consistent pattern.

The Flex 3401 is a perfect example of this.

The FLEX XC 3401 Orbital Polisher is a true forced-rotation dual action polisher! This dual action gives the Flex XC3401 superior paint correction ability. The FLEX XC3401 quickly removes swirls, scratches, oxidation and other paint defects that can’t be removed by other dual action polishers.

This polisher is not limited to paint correction, in fact it's extremely versatile. The orbital motion of the FLEX XC 3401 Polisher makes it ideal for polishing and waxing too! This orbital polishing action is what makes the Flex XC3401 a safe polisher to use and very effective.

Hopefully this helps answer any questions you may have about choosing a buffer. If you have any questions we are always available by email at support@detailingconnect.com or on our social media @detailingconnect on both Facebook and Instagram.

Below is a sample of what a buffer can do for your vehicles finish.